Product Enviroment

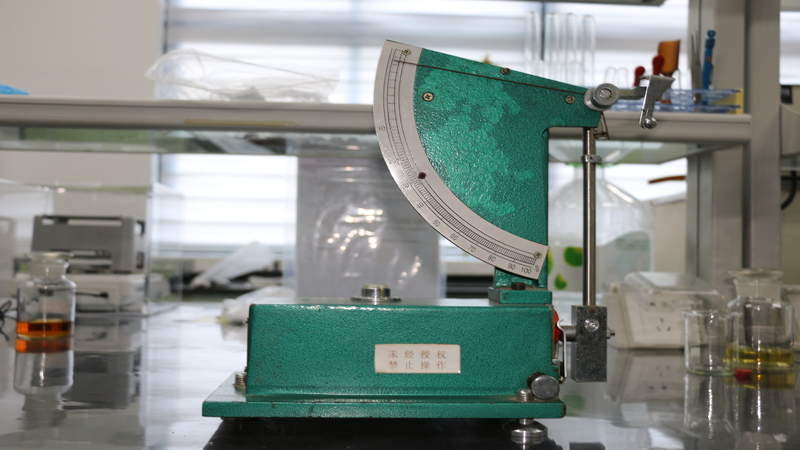

Laboratory Equipment

Factory Warehousing

Our state-of-the-art factory warehousing system ensures the timely and efficient delivery of our high-quality product. With advanced inventory management software and a meticulously organized warehouse, we can quickly fulfill orders and meet the demands of our global customer base. Our dedicated team of logistics experts is committed to providing exceptional service and ensuring that your order arrives on time and in perfect condition.

Our Equipment

- CNC Machining Centers: These versatile machines are used to create precision parts for check valves, such as valve bodies, discs, and seats.

- Lathes: Lathes are employed to shape cylindrical components like valve stems and bushings.

- Milling Machines: Milling machines are used to create complex shapes and features on valve components.

- Grinding Machines: Grinding machines are used to achieve precise tolerances and smooth finishes on valve surfaces.

- Welding Equipment: Welding is used to join different parts of the check valve together, such as the body and disc.

- Heat Treatment Furnaces: Heat treatment processes are used to improve the hardness, strength, and durability of valve materials.

- Assembly Stations: Assembly stations are equipped with tools and fixtures to assemble the various components of the check valve.

- Testing Equipment: Testing equipment is used to verify the performance and quality of the finished check valves, including pressure testing, leak testing, and cycle testing.

- Quality Control Instruments: Quality control instruments, such as calipers, micrometers, and surface roughness testers, are used to ensure that the check valves meet the required specifications.

Staff Production

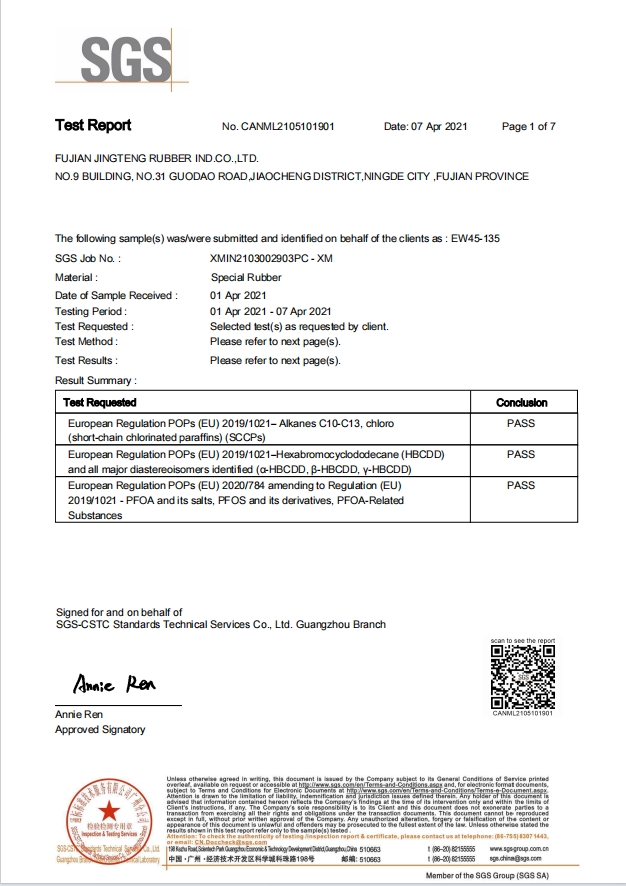

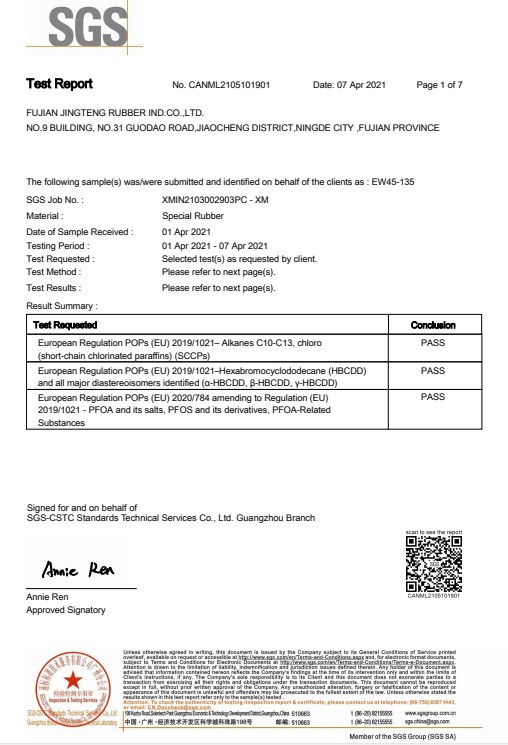

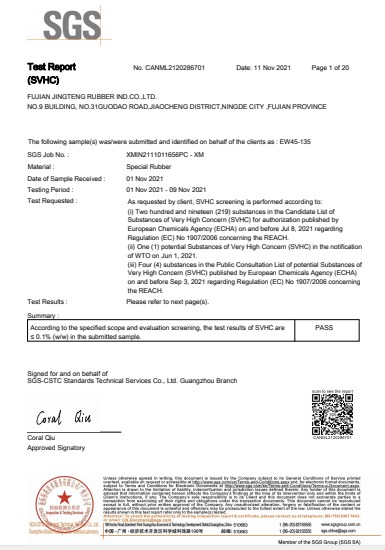

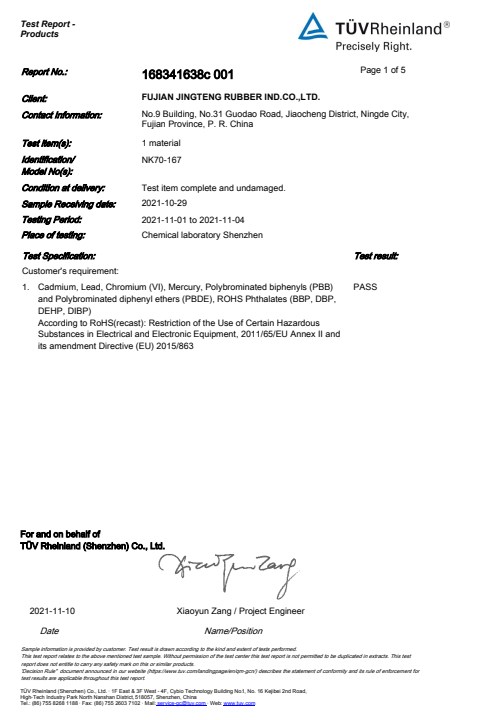

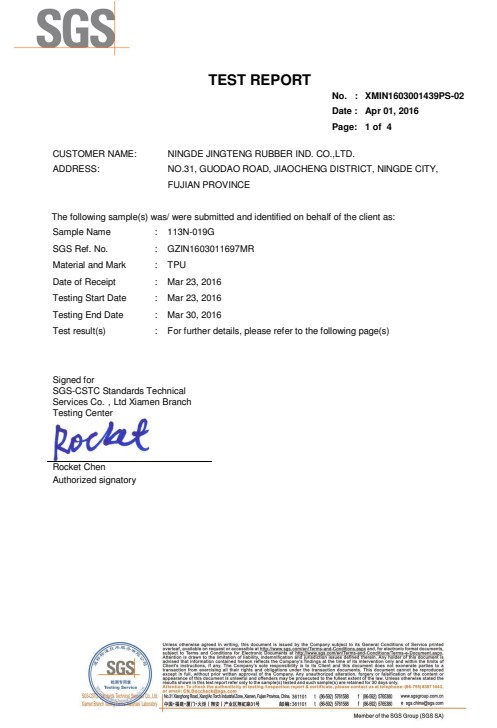

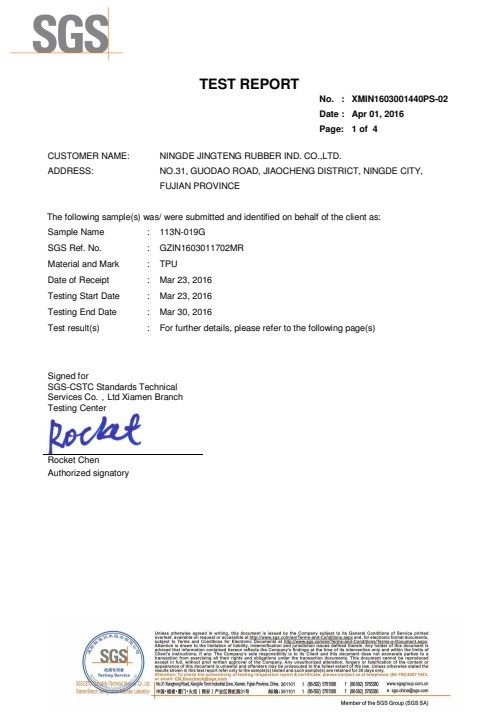

Product Certification

Contact Us Now

Enter your inquiry details, We will reply you in 24 hours.

Name can't be empty

E-mail can't be empty

Company can't be empty

Phone can't be empty

Phone

Products can't be empty

Products you want

Message can't be empty

Verification code error

Clear