Professional Garden Tools Parts Manufacturer in China

Garden Tools Parts are the individual pieces that come together to create the tools we rely on to cultivate our gardens. These components, which can vary widely in size and function, play a critical role in the durability, performance, and overall user experience of gardening equipment. Whether you're a seasoned gardener or a novice, understanding garden tool parts is essential for maintaining your tools and ensuring they last for years to come.

LB.0003 Fuel Shut Off Valve Service Grommet Bushing for Plastic Gas Tank Generator Garden Tool Parts

LB.0003 Oil switch is a switch device used to control oil flow, commonly used in hydraulic systems, lubrication systems, and oil control systems. It changes the internal path of the valve body by rotating or moving the handle to control the flow direction and stop of oil. It has the characteristics of compact structure, high reliability, and easy operation.LB.0002 Fuel Shut Off Valve Garden Tool Parts

LB.0002 Oil switch is a switch device used to control oil flow, commonly used in hydraulic systems, lubrication systems, and oil control systems. It changes the internal path of the valve body by rotating or moving the handle to control the flow direction and stop of oil. It has the characteristics of compact structure, high reliability, and easy operation.LB.0001 Shutoff Valve Inline Fuel Cut Off Valve Garden Tool Parts

LB.0001 Oil switch is a switch device used to control oil flow, commonly used in hydraulic systems, lubrication systems, and oil control systems. It changes the internal path of the valve body by rotating or moving the handle to control the flow direction and stop of oil. It has the characteristics of compact structure, high reliability, and easy operation.PT.1006 Red primer bulb small chainsaw carburetor pump kit fuel size for garden tool

Primer bulb is used as a component in mechanical components to assist the carburetor in feeding oil, and in a specific situation, it also serves to maintain a constant lubricating oil level in the bearing box. It is a press type product that supplies the medium to the required system through the cyclic action of press and relaxation.OT.1255 electrical switch high voltage switch power switch switch gear right angle oil switch

A right angle oil switch is a switch device used to control oil flow, commonly used in hydraulic systems, lubrication systems, and oil control systems. It changes the internal path of the valve body by rotating or moving the handle to control the flow direction and stop of oil. It has the characteristics of compact structure, high reliability, and easy operation.OT.1206 isolator switch Oil switch transformer switch oil switch Garden Tool Parts

Oil switch is a switch device used to control oil flow, commonly used in hydraulic systems, lubrication systems, and oil control systems. It changes the internal path of the valve body by rotating or moving the handle to control the flow direction and stop of oil. It has the characteristics of compact structure, high reliability, and easy operation.PT.1006 small chainsaw carburetor primer bulb pump kit fuel size for garden tool primer bulb

Primer bulb is used as a component in mechanical components to assist the carburetor in feeding oil, and in a specific situation, it also serves to maintain a constant lubricating oil level in the bearing box. It is a press type product that supplies the medium to the required system through the cyclic action of press and relaxation.PT.1006 blue TPU primer bulb chainsaw carburetor pump garden tool parts

PT.1006 Primer bulb is used as a component in mechanical components to assist the carburetor in feeding oil, and in a specific situation, it also serves to maintain a constant lubricating oil level in the bearing box. It is a press type product that supplies the medium to the required system through the cyclic action of press and relaxation.PT.1006 transparent primer bulb small chainsaw carburetor pump kit fuel size for garden tool parts

Primer bulb is used as a component in mechanical components to assist the carburetor in feeding oil, and in a specific situation, it also serves to maintain a constant lubricating oil level in the bearing box. It is a press type product that supplies the medium to the required system through the cyclic action of press and relaxation.PT.1007 red primer bulb garden tool parts

PT.1007 Primer bulb is used as a component in mechanical components to assist the carburetor in feeding oil, and in a specific situation, it also serves to maintain a constant lubricating oil level in the bearing box. It is a press type product that supplies the medium to the required system through the cyclic action of press and relaxation.PT.1007 pink Carburetor Parts Fuel Primer Bulb Garden Tool Parts

PT.1007 Primer bulb is used as a component in mechanical components to assist the carburetor in feeding oil, and in a specific situation, it also serves to maintain a constant lubricating oil level in the bearing box. It is a press type product that supplies the medium to the required system through the cyclic action of press and relaxation.PT.1007 transparent primer bulb snow sweeper parts garden tool parts

PT.1007 Primer bulb is used as a component in mechanical components to assist the carburetor in feeding oil, and in a specific situation, it also serves to maintain a constant lubricating oil level in the bearing box. It is a press type product that supplies the medium to the required system through the cyclic action of press and relaxation.Engine Water Pump Gasket O Ring Garden Tool Parts

Rubber seal is a device used to prevent gas or liquid leakage, usually made of rubber material. It is usually installed between sealing parts and maintains a tight seal through good compressibility and elasticity. Seals are widely used, including automotive, agriculture, construction, chemical industry, medical equipment, mechanical equipment, food processing and pharmaceuticals.Rubber Seal Black Carburetor Parts Carburetor Diaphragm Garden Tool Parts

Carburetor diaphragm is a small, flexible part of a carburetor that helps regulate the fuel and air mixture for proper combustion in an engine. It is typically made of rubber or other flexible material and is located in the carburetor's top cover or float bowl.New Stens OEM Fuel Filter Shop Pack Garden Tool Parts

Fuel filter is an essential part of the fuel system of a vehicle or engine that helps to remove impurities and contaminants from the fuel before it reaches the engine. The primary function of a fuel filter is to prevent dirt, rust, and other contaminants from entering the fuel line and clogging the fuel injectors or carburetor.High quality China Hot Selling Garden Tools Chainsaw Parts Black Bottom Fuel Filter

Fuel filter is an essential part of the fuel system of a vehicle or engine that helps to remove impurities and contaminants from the fuel before it reaches the engine. The primary function of a fuel filter is to prevent dirt, rust, and other contaminants from entering the fuel line and clogging the fuel injectors or carburetor.Replacement Fuel Filter Chainsaw Parts Garden Tool Parts

Fuel filter is an essential part of the fuel system of a vehicle or engine that helps to remove impurities and contaminants from the fuel before it reaches the engine. The primary function of a fuel filter is to prevent dirt, rust, and other contaminants from entering the fuel line and clogging the fuel injectors or carburetor.Inlet Pipe Chainsaw Intake Manifold - NEW STYLE

Intake manifold is a component in the engine that distributes air and fuel mixture to each cylinder of the engine. It is responsible for directing the air-fuel mixture from the carburetor or fuel injection system to the intake ports and ultimately to the combustion chambers. The intake manifold is typically made of cast aluminum or plastic and is bolted to the engine block. It is designed to optimize airflow and fuel delivery, ensuring that each cylinder receives the precise amount of air and fuel required for efficient combustion. The shape and size of the intake manifold can significantly affect the performance of the engine, and many high-performance engines feature custom-designed intake manifolds to maximize power output.Small Parts, Big Impact: Quality Primer Bulbs, Gasket, Tubes and Joints for Different Project

1. Introduction

When working on any kind of machinery, from small engines to complex systems, the value of high-quality small parts cannot be overstated. These seemingly insignificant components, such as primer bulbs, gaskets, tubes, and joints, often play critical roles in the performance and longevity of equipment. They ensure that everything runs smoothly, and when they fail, even the most advanced systems can grind to a halt. In fact, it’s easy to overlook these tiny parts, but the impact they have is undeniable.

But what makes a primer bulb, gasket, or a tube and joint truly reliable? It’s all about the quality of materials, precision in design, and ensuring compatibility with the machinery they’re used in. Whether you’re working on an automotive project, maintaining outdoor equipment, or repairing household machines, understanding the importance of these small parts is key to making informed choices.

In this article, we'll dive deep into how these small parts — primer bulbs, gaskets, tubes, and joints — play essential roles in various projects, why quality matters, and how you can select the right components for your needs. After all, when it comes to ensuring the efficiency and durability of any system, these tiny but mighty parts deserve your attention!

2. Fundamentals of These Parts

To truly appreciate the impact of primer bulbs, gaskets, tubes, and joints, it’s important to understand their fundamentals. Let’s break down each component, exploring its purpose, functionality, and what makes it crucial in various applications.

Primer Bulbs

- What They Are:

- How They Work:

- Why Quality Matters:

Gaskets

- What They Are:

- How They Work:

- Why Quality Matters:

Tubes

- What They Are:

- How They Work:

- Why Quality Matters:

Joints

- What They Are:

- How They Work:

- Why Quality Matters:

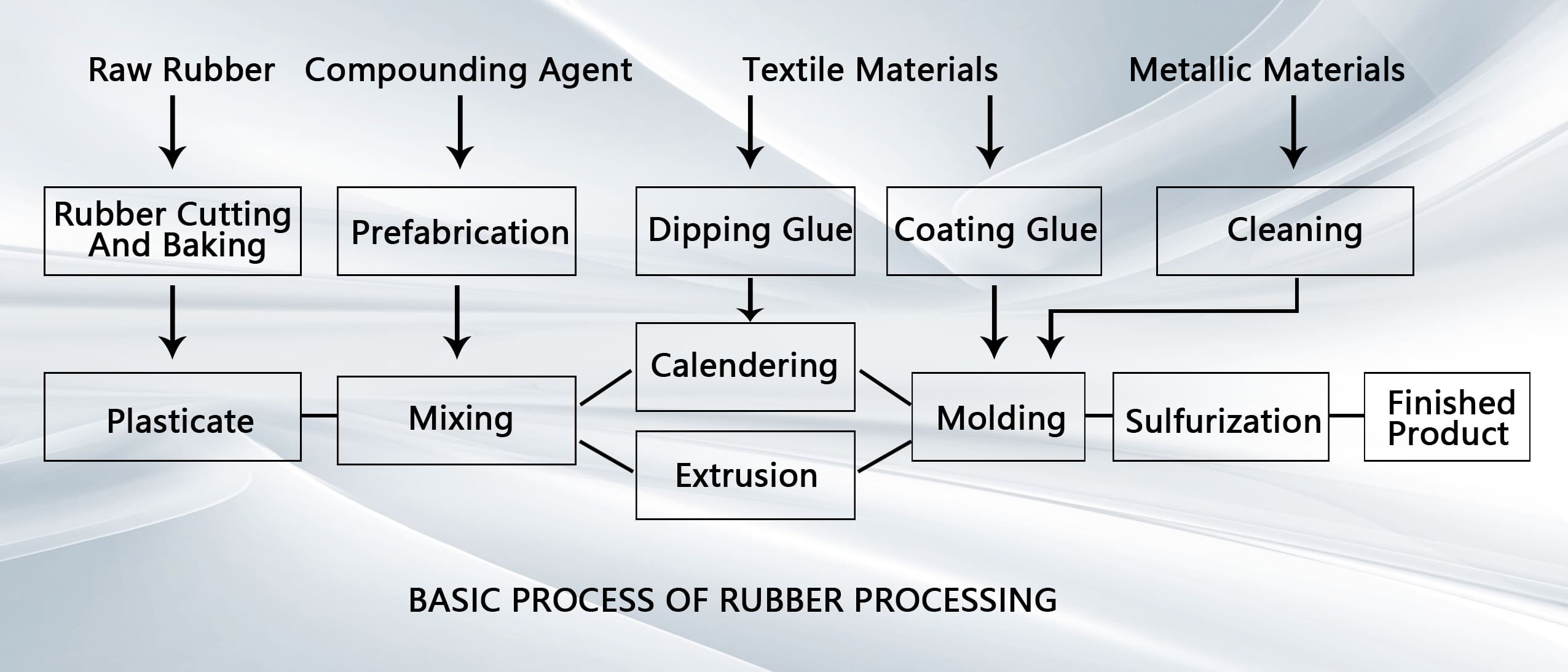

3. Production Process of These Parts

The journey from raw materials to the final products we rely on — primer bulbs, gaskets, tubes, and joints — is a meticulous process that requires precision, quality control, and expertise. Each part has its own unique production methodology, but there are some commonalities in terms of the steps involved. Let’s take a closer look at how these essential components are manufactured.

a. Material Selection

b. Design and Engineering

c. Manufacturing Techniques

- For Primer Bulbs: The production typically involves molding processes, where heated materials are injected into molds to create the bulb's shape. This ensures uniformity and precision.

- For Gaskets: Gasket manufacturing often uses die-cutting or compression molding. In die-cutting, sheets of material are punched out in the desired shapes. Compression molding involves pressing heated materials into molds, creating strong and reliable seals.

- For Tubes: Tube production usually involves extrusion, where raw plastic or metal is forced through a shaped die to create long, continuous tubes. These are then cut to size and finished as needed.

- For Joints: The manufacturing of joints may include machining, where raw materials are shaped into precise components using tools and machinery. Some joints might also be molded or cast, depending on their design.

d. Quality Control

- Ensuring Reliability: Once the components are manufactured, rigorous quality control checks are performed. This includes inspecting the dimensions, materials, and overall functionality of each part.

- Testing: Each batch of products undergoes testing to ensure they meet industry standards and specifications. This could involve pressure testing for tubes, seal tests for gaskets, and functionality tests for primer bulbs.

- Certification: Many manufacturers obtain certifications that demonstrate compliance with relevant industry standards, further assuring customers of the product's quality.

4. Choosing Best Mini Check Valve Manufacturer from China

Choosing the right mini check valve manufacturer from China requires careful consideration of multiple factors. By defining your requirements, conducting thorough research, and evaluating potential manufacturers, you can ensure that you select a partner that meets your needs. Remember, the right manufacturer can significantly impact your project's success, making it worth the effort to find one that aligns with your standards and expectations. Happy sourcing!