Trustly and Professional Miniature Check Valve Manufacturer from China

Welcome to Valve Kingdom, your trusted Miniature Check Valve manufacturer. Our range includes one way check valves designed for reliable performance in various applications. Explore our innovative duckbill valves and versatile umbrella valves, all crafted to meet stringent quality standards. Discover how our miniature check valves can enhance your systems with efficiency and durability.

Crafted with precision, our products are a testament to our commitment to quality. Utilizing top-tier materials, state-of-the-art molds, and cutting-edge manufacturing techniques, we produce high-performance solutions. Our class 10,000 cleanroom guarantees that every product meets the highest standards before reaching our customers.From concept to completion, we prioritize quality in every step of the manufacturing process. Premium materials, precision tooling, and advanced production techniques are the foundation of our high-performance products.

One Way Check Plastic Rubber Duckbill Valve

One Way Check Plastic Rubber Duckbill Valve used to control the flow of fluids and gases. It is usually made of a flexible elastomer such as rubber or silicone, and is designed in the shape of a flattened cone, with a slit at the top. When fluid or gas flows through the valve in the correct direction, the pressure forces the slit closed, preventing backflow. When the pressure is reversed, the valve opens, allowing the fluid or gas to flow through in the opposite direction. Duckbill valves are commonly used in medical devices, industrial applications, and in automotive applications where they are used to prevent fuel tank overflow during refueling.Small Non Return Valve Rubber Duckbill Valve

Food Grade ODE OEM Silicone Rubber Air Release Valve Silicone Duckbill Valve used to control the flow of fluids and gases. It is usually made of a flexible elastomer such as rubber or silicone, and is designed in the shape of a flattened cone, with a slit at the top. When fluid or gas flows through the valve in the correct direction, the pressure forces the slit closed, preventing backflow. When the pressure is reversed, the valve opens, allowing the fluid or gas to flow through in the opposite direction. Duckbill valves are commonly used in medical devices, industrial applications, and in automotive applications where they are used to prevent fuel tank overflow during refueling.Food Grade ODE OEM Silicone Rubber Air Release Valve Silicone Duckbill Valve

Food Grade ODE OEM Silicone Rubber Air Release Valve Silicone Duckbill Valve used to control the flow of fluids and gases. It is usually made of a flexible elastomer such as rubber or silicone, and is designed in the shape of a flattened cone, with a slit at the top. When fluid or gas flows through the valve in the correct direction, the pressure forces the slit closed, preventing backflow. When the pressure is reversed, the valve opens, allowing the fluid or gas to flow through in the opposite direction. Duckbill valves are commonly used in medical devices, industrial applications, and in automotive applications where they are used to prevent fuel tank overflow during refueling.Aquarium Check Valve One Way Air Check Valve Duckbill Check

Aquarium Check Valve One Way Air Check Valve Duckbill Check used to control the flow of fluids and gases. It is usually made of a flexible elastomer such as rubber or silicone, and is designed in the shape of a flattened cone, with a slit at the top. When fluid or gas flows through the valve in the correct direction, the pressure forces the slit closed, preventing backflow. When the pressure is reversed, the valve opens, allowing the fluid or gas to flow through in the opposite direction. Duckbill valves are commonly used in medical devices, industrial applications, and in automotive applications where they are used to prevent fuel tank overflow during refueling.Silicone Rubber Core Engine Pressure Relief Rubber Duckbill Valve

Silicone Rubber Non Return Check Valve Core Engine Pressure Relief Rubber One Way Valve Duckbill Valve used to control the flow of fluids and gases. It is usually made of a flexible elastomer such as rubber or silicone, and is designed in the shape of a flattened cone, with a slit at the top. When fluid or gas flows through the valve in the correct direction, the pressure forces the slit closed, preventing backflow. When the pressure is reversed, the valve opens, allowing the fluid or gas to flow through in the opposite direction. Duckbill valves are commonly used in medical devices, industrial applications, and in automotive applications where they are used to prevent fuel tank overflow during refueling.Micro Air Rubber Valve For Water System Duckbill Valve

Micro Air Rubber Valve Seal For Water System Duckbill Valve is a one-way valve used to control the flow of fluids and gases. It is usually made of a flexible elastomer such as rubber or silicone, and is designed in the shape of a flattened cone, with a slit at the top. When fluid or gas flows through the valve in the correct direction, the pressure forces the slit closed, preventing backflow. When the pressure is reversed, the valve opens, allowing the fluid or gas to flow through in the opposite direction. Duckbill valves are commonly used in medical devices, industrial applications, and in automotive applications where they are used to prevent fuel tank overflow during refueling.Eco Friendly Check Valve Small Valve Duckbill Valve

Eco-Friendly Duckbill Check Valve Non-Return Valve Small Air Valve Duckbill Valve is a one-way valve used to control the flow of fluids and gases. It is usually made of a flexible elastomer such as rubber or silicone, and is designed in the shape of a flattened cone, with a slit at the top. When fluid or gas flows through the valve in the correct direction, the pressure forces the slit closed, preventing backflow. When the pressure is reversed, the valve opens, allowing the fluid or gas to flow through in the opposite direction. Duckbill valves are commonly used in medical devices, industrial applications, and in automotive applications where they are used to prevent fuel tank overflow during refueling.Plastic One Way Medical Diaphragm Valve

CT.0050 Diaphragm valve is a type of valve that uses a flexible diaphragm to regulate the flow of fluids.1/8 Inch CT.0028 Plastic Check One Way Diaphragm Valve

Diaphragm valve can completely isolate the corrosive medium in the flow channel from all driving components, thus eliminating the drawbacks of ordinary valves such as "running, bubbling, dripping, and leaking".8mm JT.1003 Red Rubber Duckbill Valve

JT.1003 Duckbill valve is a one-way valve used to control the flow of fluids and gases. It is usually made of a flexible elastomer such as rubber or silicone, and is designed in the shape of a flattened cone, with a slit at the top. When fluid or gas flows through the valve in the correct direction, the pressure forces the slit closed, preventing backflow. When the pressure is reversed, the valve opens, allowing the fluid or gas to flow through in the opposite direction. Duckbill valves are commonly used in medical devices, industrial applications, and in automotive applications where they are used to prevent fuel tank overflow during refueling.3/16 Inch CT.0029 Fuel Check Valve Plastic Check One Way Diaphragm Valve

CT.0029 Diaphragm valve is a type of valve that uses a flexible diaphragm to regulate the flow of fluids.5mm JT.1033 Red Rubber Duckbill Valve

JT.1033 Duckbill valves are used for a wide variety of applications where a one-way checking function needs to be established.1/4 Inch CT.0017 Plastic Check One Way Diaphragm Valve

CT.0017 Diaphragm valve is a type of valve that uses a flexible diaphragm to regulate the flow of fluids.5/16 Inch CT.0030 Plastic Check One Way Diaphragm Valve

CT.0030 Diaphragm valve is a type of valve that uses a flexible diaphragm to regulate the flow of fluids.8mm JT.1034 Black One Way Check Rubber Duckbill Valve

Duckbill valve is a one-way valve used to control the flow of fluids and gases. It is usually made of a flexible elastomer such as rubber or silicone, and is designed in the shape of a flattened cone, with a slit at the top. When fluid or gas flows through the valve in the correct direction, the pressure forces the slit closed, preventing backflow. When the pressure is reversed, the valve opens, allowing the fluid or gas to flow through in the opposite direction. Duckbill valves are commonly used in medical devices, industrial applications, and in automotive applications where they are used to prevent fuel tank overflow during refueling.15.2mm JT.1064 Red Rubber Duckbill Valve

15.2mm JT1064 Red Rubber Duckbill valves are used for a wide variety of applications where a one-way checking function needs to be established.What Is One Way Check Valve?

A one-way check valve, often referred to simply as a check valve, is a crucial component in fluid control systems that allows flow in only one direction. This type of valve features a design that ensures the valve opens to permit fluid passage when the flow is in the correct direction. Conversely, if the flow attempts to reverse, the valve automatically closes, preventing backflow. This functionality is typically achieved through a spring mechanism or a movable flap that responds to changes in pressure. One-way check valves are essential in a variety of applications, including plumbing, HVAC systems, and industrial processes, where maintaining the intended flow direction is critical for system efficiency and safety.

Miniature Check Valve Design

- Valve Shape

The design of the valve significantly impacts both sealing efficiency and flow characteristics. Common configurations include cylindrical and conical shapes, each offering distinct performance benefits.

- Spring Force

The spring force is critical in determining the valve's opening pressure and closing speed, ensuring reliable operation under varying flow conditions.

- Valve Seat Design

The choice of material and surface treatment for the valve seat plays a crucial role in achieving effective sealing, enhancing the overall reliability of the valve.

- Dimension Tolerance

Maintaining precise dimensional tolerances is essential for ensuring interchangeability and optimal sealing performance, which are vital for the valve's functionality in various applications.

Function of Miniature Check Valve

A miniature check valve serves a critical role in fluid control systems by allowing fluid to flow in only one direction, thereby preventing backflow. This functionality is essential for maintaining the integrity and efficiency of various applications, from small-scale plumbing systems to intricate industrial processes.

-

Preventing Backflow

The primary function of a miniature check valve is to prevent backflow, which can lead to contamination, pressure loss, and potential damage to equipment. When fluid flows in the intended direction, the valve opens, allowing the medium to pass through. However, if the flow attempts to reverse, the valve automatically closes, creating a barrier that stops the backward movement of fluid.

-

Pressure Regulation

Miniature check valves can also help regulate pressure within a system. By ensuring that fluid does not flow back into an upstream system, they help maintain consistent pressure levels. This is particularly important in applications where pressure fluctuations can affect performance, such as in hydraulic systems or fluid delivery networks.

-

Space Efficiency

Due to their small size, miniature check valves are ideal for applications where space is limited. Their compact design allows them to fit seamlessly into tight installations without compromising functionality. This is especially beneficial in areas such as medical devices, automotive systems, and consumer products.

-

Versatility

These valves are versatile and can be used in various applications, including water supply systems, gas lines, and chemical processing. They can handle a range of fluids, from water to oils and even aggressive chemicals, depending on the materials used in their construction.

-

Material Considerations

The materials used in miniature check valves significantly influence their performance and longevity. Common materials include plastics, metals, and elastomers, each selected based on the specific requirements of the application, such as chemical compatibility and temperature resistance.

In summary, miniature check valves are essential components in fluid control systems, providing crucial functions like preventing backflow, regulating pressure, and offering space-efficient solutions for a wide variety of applications. Their reliable performance and versatility make them indispensable in many industries.

Miniature Check Valve Application Areas

Miniature check valves are widely used across various industries due to their compact size, reliability, and efficient backflow prevention capabilities. Here are some key application areas where these valves play a crucial role:

1. Medical Devices

In medical applications, miniature check valves are integral to devices such as infusion pumps, respiratory equipment, and blood analyzers. They ensure that fluids, including medications and blood, flow in the correct direction without contamination or backflow, which is critical for patient safety.

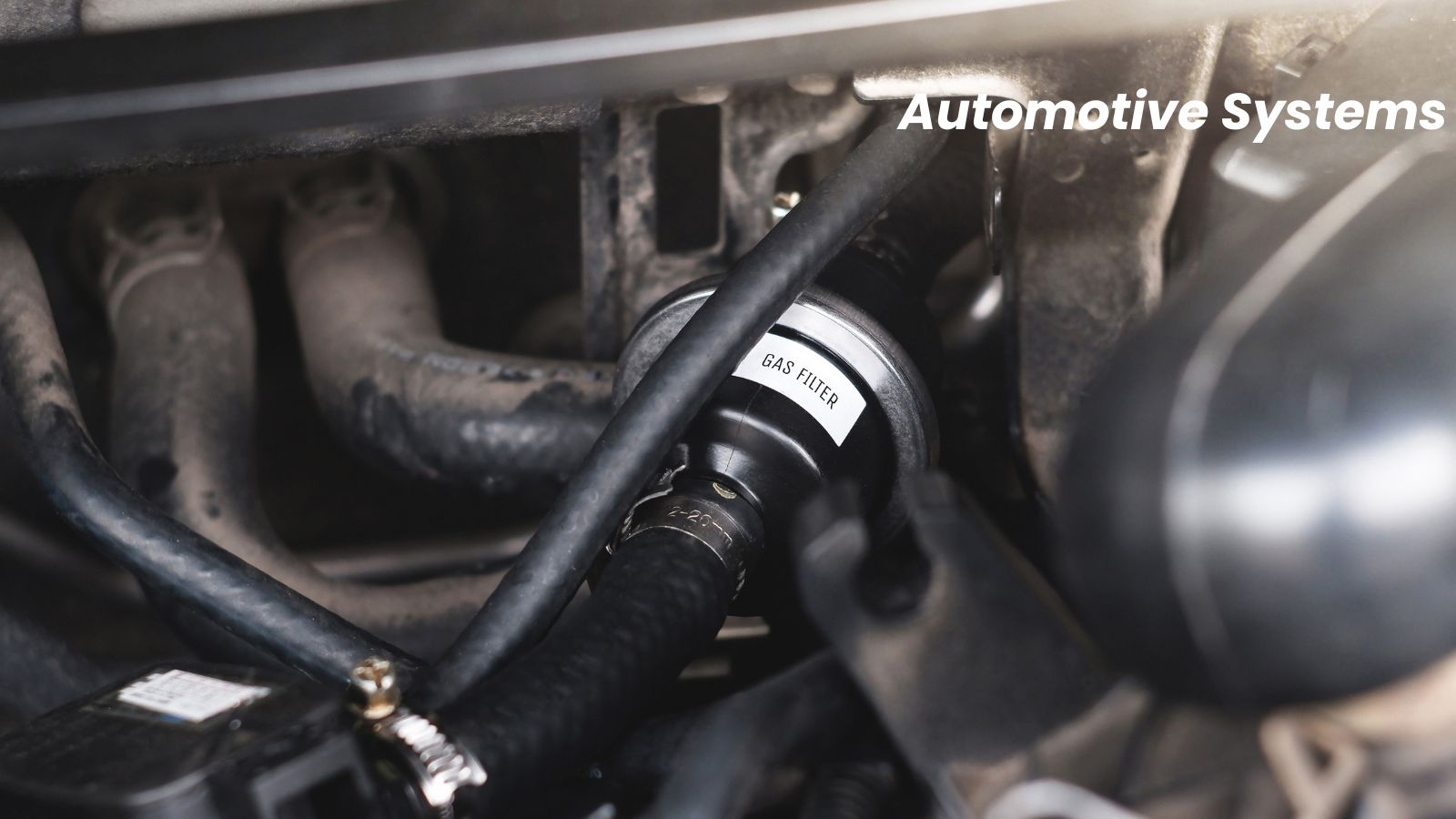

2. Automotive Systems

In automotive engineering, miniature check valves are employed in fuel systems, coolant circuits, and brake systems. They help maintain pressure, prevent fuel from flowing back into the tank, and ensure efficient operation of hydraulic brake systems, contributing to overall vehicle performance and safety.

3. Industrial Processes

Miniature check valves are utilized in various industrial applications, including chemical processing, fluid transport, and manufacturing operations. They are essential for maintaining flow direction in piping systems, preventing backflow that could cause cross-contamination or damage to equipment.

4. Consumer Products

Many everyday consumer products, such as water dispensers, coffee machines, and spray bottles, incorporate miniature check valves. These valves help control fluid flow and ensure that liquids are dispensed correctly and efficiently, enhancing user experience and product reliability.

5. HVAC Systems

In heating, ventilation, and air conditioning (HVAC) systems, miniature check valves are used to manage the flow of refrigerants and other fluids. They help maintain system efficiency by preventing backflow that could disrupt pressure balances and lead to system inefficiencies.

6. Aquaculture and Water Treatment

In aquaculture systems and water treatment processes, miniature check valves are crucial for controlling the flow of water and ensuring the proper operation of pumps and filtration systems. They help prevent backflow, which can lead to contamination or inefficient water circulation.

7. Fluid Delivery Systems

These valves are vital in fluid delivery systems for pharmaceuticals, food and beverages, and chemicals. By ensuring that liquids flow in the desired direction, miniature check valves help maintain product integrity and prevent spoilage or contamination.

8. Aerospace Applications

In aerospace engineering, miniature check valves are used in hydraulic systems, fuel lines, and environmental control systems. They play a critical role in ensuring that fluids are directed appropriately and that systems operate reliably under various conditions.

Miniature check valves are essential components that enhance the efficiency and reliability of various systems across multiple industries. As a premier manufacturer dedicated to the B2B market, we focus on providing top-quality one way check valves tailored to meet the specific needs of our clients. Our expertise in crafting miniature check valve solutions ensures that you receive products that not only meet stringent quality standards but also drive operational success. Partner with us, a trusted name among miniature check valve manufacturers, to secure the performance and durability your applications demand. Experience the difference with our innovative designs and reliable solutions tailored for your business needs.